|

By

1990, Latham production was in full swing, and the first

customer cars were starting to reach completion stage.

Once again, it was Ian Hyne, now penning articles for

Kitcars Intrernational, who came to look at two newly

completed examples . . . By

1990, Latham production was in full swing, and the first

customer cars were starting to reach completion stage.

Once again, it was Ian Hyne, now penning articles for

Kitcars Intrernational, who came to look at two newly

completed examples . . .

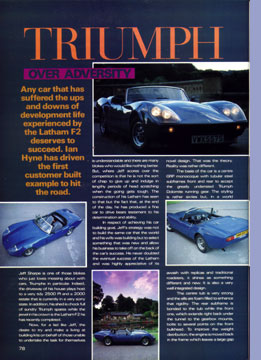

Any

car that has suffered the ups and downs of development

life experienced by the Latham F2 deserves to succeed.

Ian Hyne has driven the first customer built example

to hit the road.

Jeff

Sharpe is one of those blokes who just loves messing

about with cars, Triumphs in particular. Indeed, the

driveway of his house plays host to a very tidy 2500

PI and a 2000 estate that is currently in a very sorry

state. In addition, his shed is chock full of sundry

Triumph spares while the jewel in his crown is the Latham

F2 he has recently completed.

Now, for a lad like Jeff, the desire to try and make

a living at building kits on behalf of those unable

to undertake the task for themselves is understandable

and there are many blokes who would like nothing better.

But, where Jeff scores over the competition is that

he is not the sort of chap to give up and indulge in

lengthy periods of head scratching when the going gets

tough. The construction of his Latham has seen to that

but the fact that, at the end of the day, he has produced

a fine car to drive bears testament to his determination

and ability.

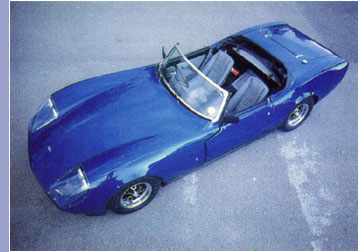

In respect of achieving his car building goal, Jeff's

strategy was not to build the same car that the world

and his wife was building but to select something that

was new and allow his business to take off on the back

of the car's success. He never doubted the eventual

success of the Latham and was highly appreciative of

its novel design. That was the theory. Reality was rather

different.

In respect of achieving his car building goal, Jeff's

strategy was not to build the same car that the world

and his wife was building but to select something that

was new and allow his business to take off on the back

of the car's success. He never doubted the eventual

success of the Latham and was highly appreciative of

its novel design. That was the theory. Reality was rather

different.

The basis of the car is a centre GRP monocoque with

tubular steel subframes front and rear to accept the

greatly underrated Triumph Dolomite running gear. The

styling is rather sixties but, in a world awash with

replicas and traditional roadsters, it shines as something

different and new. It is also a very well integrated

design.

The centre tub is very strong and the sills are foam

filled to enhance that rigidity. The rear subframe is

bonded to the tub while the front one, which extends

right back under the tunnel to the gearbox mounts, bolts

to several points on the front bulkhead. To improve

the weight distribution, the engine is moved back in

the frame which leaves a large gap between the radiator

and the engine and this has been utilised for the modified

suspension. The Dolomite donor used a coilspring damper

unit mounted above the upper wishbone but since the

Latham does not have room for this, it has been modified.

The top wishbone is now a rocking arm and the coilspring

damper units are mounted indboard. Simple, clever and

very effective design.

The Dolomite has been a good choice of donor vehicle

not only for its underrated mechanical base but also

for the many other parts that have been used. The instruments,

heater and controls, door releases, handles, lights,

fuel tank, wheels and tyres have all been utilised saving

quite a few quid on the build. About the only other

parts required are a screen assembly and hood from an

MGB.

The Dolomite has been a good choice of donor vehicle

not only for its underrated mechanical base but also

for the many other parts that have been used. The instruments,

heater and controls, door releases, handles, lights,

fuel tank, wheels and tyres have all been utilised saving

quite a few quid on the build. About the only other

parts required are a screen assembly and hood from an

MGB.

I have been acquainted with the Latham for a long time

now having first seen it in the early stages of development

a few years back in Penzance (see previous article

here). I later drove

the prototype car and was impressed even though it suffered

from a few shortcomings that needed attention prior

to production. (See previous article here)

Then at Stoneleigh this year, the Latham stand was graced

by a beautiful metalflake blue car owned and built by

club sec and magazine editor, Marcus Potts. I also learned

that 15 cars had been delivered to customers and that

Jeff Sharpe's was the first to hit the road. A recent

visit to the infant factory revealed several cars under

construction and yielded a pair of seat runners for

delivery to Jeff Sharpe who lives very near me so we

met to discuss his car.

It is unfortunate that Jeff's route from kit to completed

car has been very far from the plain sailing we all

hope for. The list of faults included the rear subframe

bonded in the wrong position, rear suspension pick up

points inaccurately drilled, front sub-frame badly twisted

so the tub would not sit on its support members and,

when the car was rolling, the wheels fouled the bodywork

front and rear. Thus Jeff has had to indulge in a great

deal of cutting, shutting, welding and redrilling as

well as a good bit of panel dressing.

Having

seen the photographic evidence of his problems, I can

only say that none of the cars under construction at

the factory were similarly affected. In discussing Jeff's

experience with Julia Latham she could only apologise

and say that his was the first of a batch of five kits

entrusted to sub contractors during the period in which

the company moved from Penzance to Bicester. They very

soon discovered the faults and intervened to rectify

them but Jeff, with his ability and enthusiasm, elected

to sort his car himself. Thereafter, production was

suspended in August 89, the sub contractors were issued

marching orders, new jigs were made and the GRP work,

with which she was also not happy, was brought in house.

These drastic measures and considerable financial expense

have certainly done the trick but, in spite of the dramas

of construction, Jeff is still a staunch fan of the

car and is greatly impressed with driving it. Having

seen the photographic evidence of his problems, I can

only say that none of the cars under construction at

the factory were similarly affected. In discussing Jeff's

experience with Julia Latham she could only apologise

and say that his was the first of a batch of five kits

entrusted to sub contractors during the period in which

the company moved from Penzance to Bicester. They very

soon discovered the faults and intervened to rectify

them but Jeff, with his ability and enthusiasm, elected

to sort his car himself. Thereafter, production was

suspended in August 89, the sub contractors were issued

marching orders, new jigs were made and the GRP work,

with which she was also not happy, was brought in house.

These drastic measures and considerable financial expense

have certainly done the trick but, in spite of the dramas

of construction, Jeff is still a staunch fan of the

car and is greatly impressed with driving it.

It is not a concours car, but that was never the intention.

He wanted to build a car to drive and in that, he has

succeeded. He has used the Dolomite Sprint engine giving

well over 100 mph performance. Needless to say, we didn't

come close to that on the less than perfect roads round

Bradford but the car was quick. It is also torquey which

allows you to drive in a relaxed manner which Jeff likes

best.

It's

quite a drop to the low driving seat but, once there,

the Latham seats are comfortable and there is room for

taller drivers. If there isn't, the pedals can be moved

and one car has just gone to a customer of 6' 4"

! Sitting there, the main gauges are neatly grouped

in front of you while the rest are centrally mounted

along with the heater, stereo, switches and ashtray.

For me, the gear lever and handbrake were a little far

back but I could live with it. It's

quite a drop to the low driving seat but, once there,

the Latham seats are comfortable and there is room for

taller drivers. If there isn't, the pedals can be moved

and one car has just gone to a customer of 6' 4"

! Sitting there, the main gauges are neatly grouped

in front of you while the rest are centrally mounted

along with the heater, stereo, switches and ashtray.

For me, the gear lever and handbrake were a little far

back but I could live with it.

The view over the bulbous bonnet was rather stirring

so I fired her up and off we went. Riding on Spax adjustables

set to soft, it was very smooth and just glided down

the road. Once free of traffic, the Dolomite Sprint

unit easily demonstrated its ability and the good few

bends we got a clear shot at similarly showed its cornering

prowess and grip. Indeed, the only burp in its road

manners was that the exhaust boxes kept grounding on

the big bumps. There is no more room to raise them but

the factory now fit stiffer rear springs and gas dampers

while the fertile Sharpe brain is working on his own

solution.

The only other thing I noticed was that the bonnet panel

moved about at speed. Secured either side with a lock,

it won't come undone but the factory now fit a central

lock to overcome the problem. Overall, I greatly enjoyed

the car and like Jeff, was impressed with its overall

design even if a few areas of execution could be improved.

But then, it's often the way with kit cars that the

early customers discover the faults that have been missed.

However, Jeff has built a good car that is a delight

to drive while the factory have also benefitted from

his experience and have drastically improved their product.

I take my hat off to him for his car and for the contribution

to the many Lathams that will follow.

Now, due to the time taken to build the car, Jeff's

strategy has received a severe dent and, in order to

get back on course, the Latham is for sale to fund the

next project. Of course, it could be that you don't

want want to buy it but you could use the services of

a chap with the grit, determination, inventiveness and

ability he possesses. Whatever the case, you can contact

Jeff at . . . . and, if you have detailed plans to discuss,

the New Inn round the corner is a good pub offering

excellent grub!

Latham

F2

Construction:

Suspension:

Brakes:

Engine fitted:

Max power:

Max torque:

Performance:

Engine Options:

Dimensions:

|

Specifications

GRP monocoque centre tub with 16 gauge tubular

subframes front and rear.

Front: Bottom wishbone, upper rocking arm

with inboard coilspring damper.

Rear: Four trailing arms, parallel lower,

angled upper, with coil springs and telescopic

dampers

Front: 8" discs. Rear: 8" drums

(1850cc); 9" drums (Sprint).

2 litre Dolomite Sprint, 4 valves per cylinder.

127 bhp at 5700 rpm.

122 ft lbs at 4500rpm.

0- 60 mph 5.8 seconds. Max speed 140 mph.

Dolomite 1850, 2 valves per cylinder. 91 bhp

at 5200 rpm and 105 ft lbs torque.

Overall length: 13 ft 7 ins.

Overall height: 3 ft 8 ins.

Wheelbase: 7 ft 9 ins.

Track: Front: 4 ft 5 ins.

Rear: 4 ft 2 ins.

Ground clearance: 4½ ins.

Kerb weight: 13½ cwt. |

|

With

thanks to Ian Hyne With

thanks to Ian Hyne

Kitcars International magazine,

August 1990, pages 78-80

Jeff's

car, F2034, is now with a new owner, but still resides

in Yorkshire. The red car (left), which was in the process

of being built when Ian visited the LSC Bicester factory

in 1990, was F2037. It was delivered to its expectant

owner in London in early 1991 and never heard of again.

It was a beautifully constructed car, so any news of

its current whereabouts would be much appreciated!

Kitcars International is no longer published, but was

absorbed into Kit Car:

Kitcars International is no longer published, but was

absorbed into Kit Car:

|